Our Projects

Technoviz Automation Solutions Private Limited Projects

Technoviz Automation Solutions Private Limited has a proven track record of providing high quality, custom software and automation projects. Our client list includes Fortune 500 Corporations, Government agencies, and small businesses. Our experience is broad and spans all the projects development cycle.

Remote Scada and Mobility Solutions

Remote SCADA and Mobility Solutions: Industry 4.0 looking for connectivity, mobility, cloud, and analytics kind of engineering technologies to achieve its business goals.

Ammonia-based Refrigeration automation system(Projects)

for Milk Dairy Plant.

Temperature and other critical parameters need to be managed as per the desired range as it will impact the working of all inventory products.

Case Study 01

Important and relevant information can be accessed anywhere anytime. Further, it improved productivity and causes a reduction in maintenance, operations and energy costs. Now customers can send production data to ERP & MES – and access the information to meet their business objectives.

Objective:

Technoviz Automation Solutions Private Limited has a proven track record of providing high-quality, custom software and automation projects. Our client list includes Fortune 500 Corporations, Government agencies, and small businesses. Our experience is broad and spans the Complete project development cycle.

Solution:

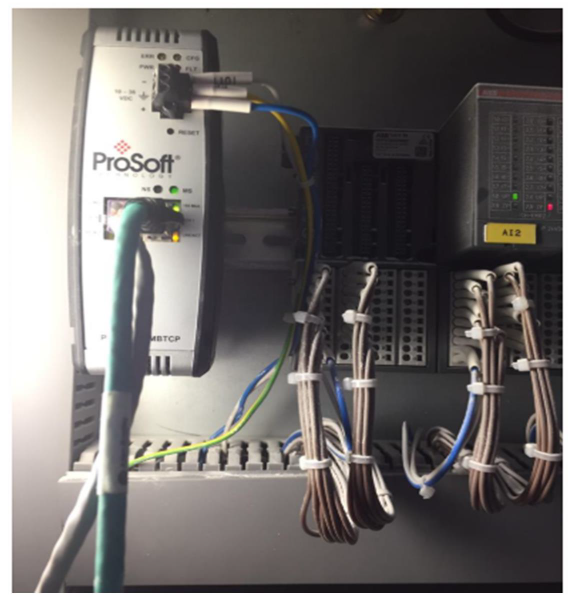

With the help of different gateways and communication protocol conversions on different network media we have successfully integrated Siemens S71500, ABB PM573 & Rockwell Compact Logix on a single platform i.e. OPC UA server while maintaining the quality of the flow of data by prioritizing it.

Case Study 02

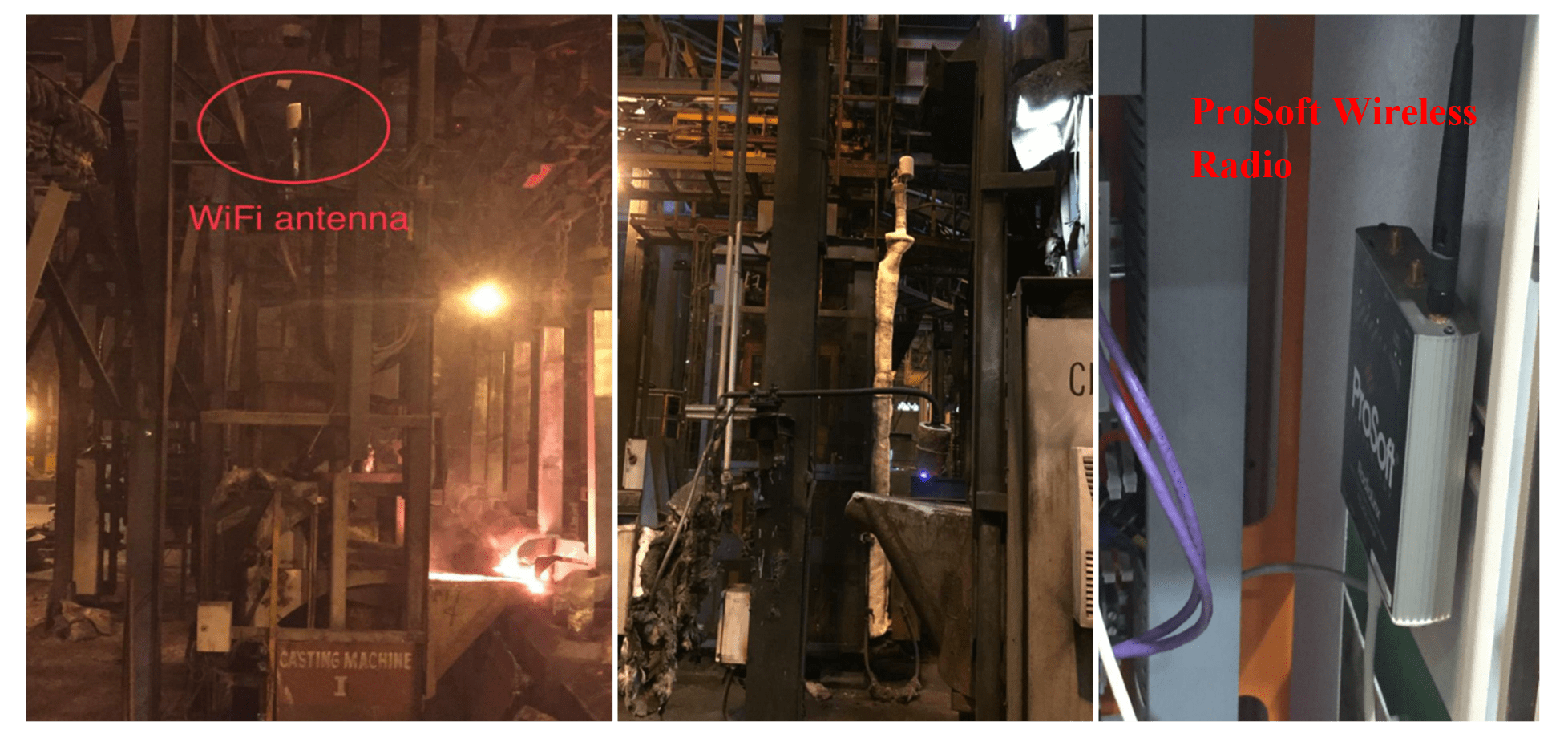

One of our Fortune 500 clients was facing a challenge in Wireless Communication, Roding Line where the temperature was around more than 600 degrees Celsius and liquid iron needs to be filled in Aluminum Slab for Cathode Reaction. All this filling process is controlled by the operator remotely and Roding Lines communicate with the main PLC Panel through a wireless communication System.

The problem was after a certain distance communication was interrupted and breakdown for a few minutes and the whole system needs to restart. It was around 1 million INR lose per hour for the company.

Objective:

To integrate different controllers and field equipment with centralize data hub to achieve Industry 4.0 norms.

Solution:

Being as domain experts we visited and reconfirm the Wireless system designed and check the data rate flow and replace the passive elements and used Multi Input Multi Output antennas by making these design level changes system is working perfectly and the customer-provided an appreciation letter for the same.

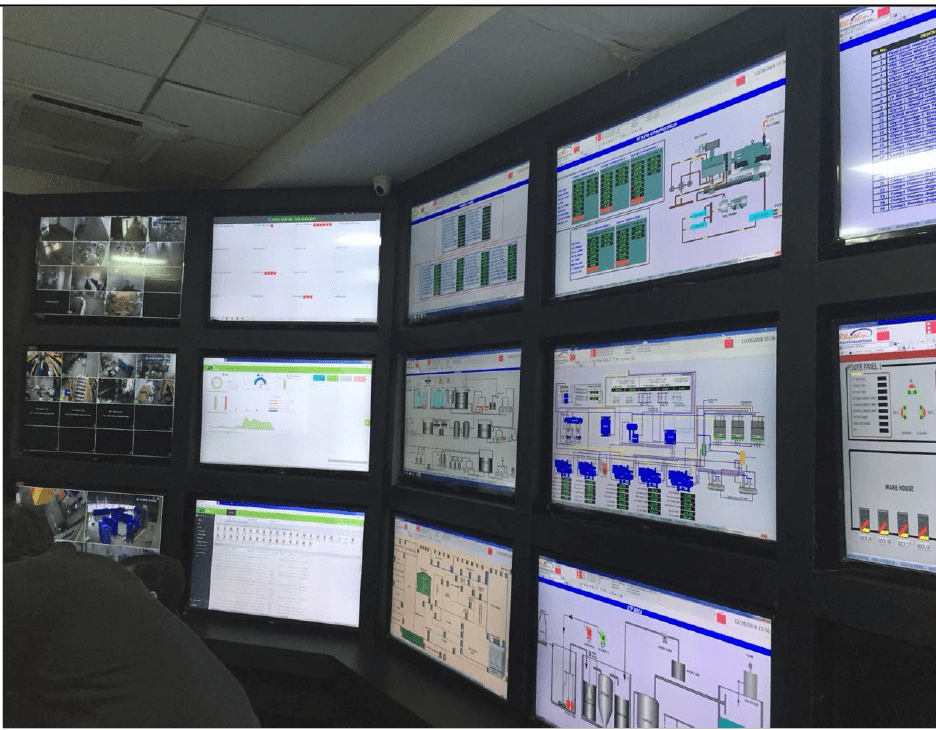

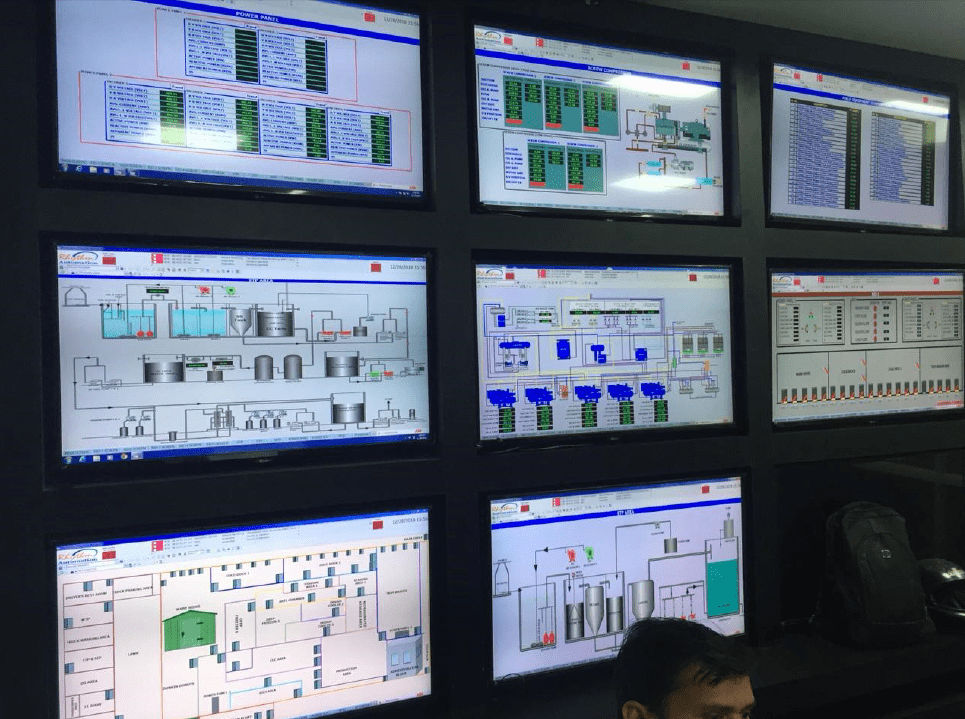

Remote Scada and Mobility Solutions

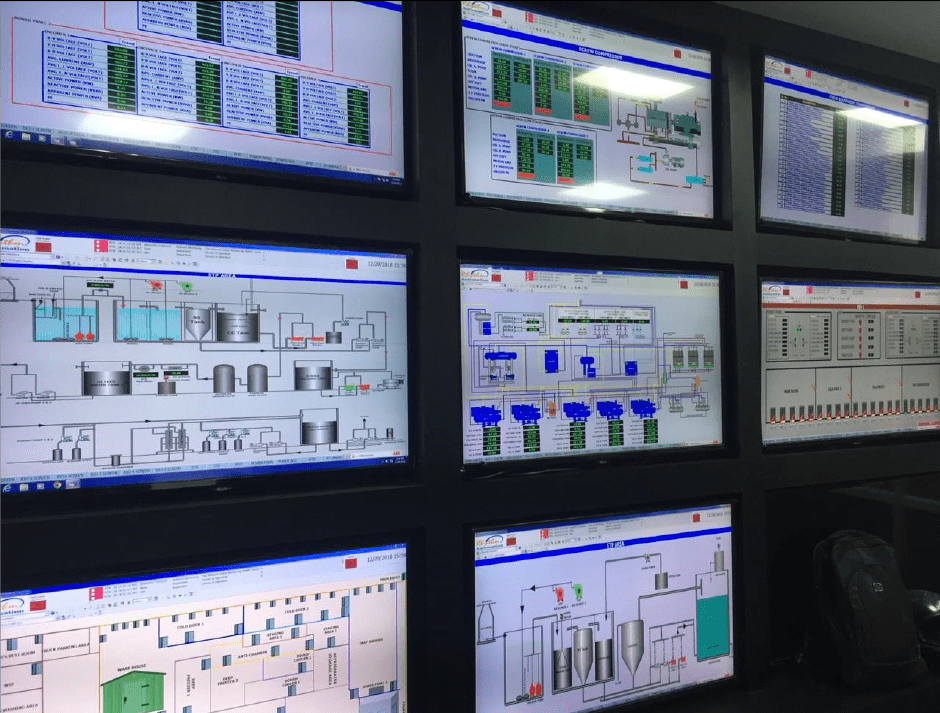

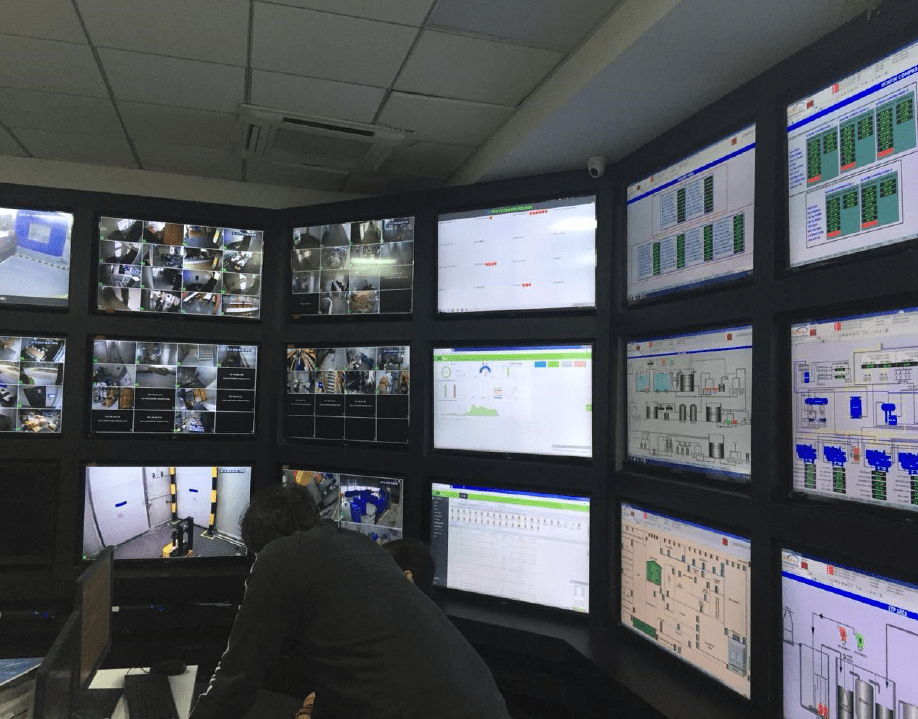

Remote SCADA and Mobility Solutions: Industry 4.0 looking for connectivity, mobility, cloud, analytics kind of engineering technologies to achieve their business goals. One of the leading companies in the food segment having a presence across the globe and manufacturing setup in India approached us for the Remote SCADA solution.

Problem:

Different units/sub-units/departments which were operating within the premises having a distance of approx. 3 K.M… Lots of energy & manpower are engaged in monitoring & fetching the data related to production & energy consumption. The company was looking for a solution in which all the information can be monitored from a centralized Control Room and can be utilized the manpower in a more effective way and also improve the quality of raw data.

Solution:

We have proposed the solution to integrate all controllers, local SCADAs & PLCs and installed one server-based Remote SCADA System in the centralized control room. For that, we have created one server room and the complete plant-related information with customized dashboards has been provided in a centralized location. Information related to production persons, maintenance persons, and quality engineers & for Top Management is available 24X7 in a relevant customized format.

Ammonia-based Refrigeration automation system for Milk Dairy Plant

Remote SCADA and Mobility Solutions: Industry 4.0 looking for connectivity, mobility, cloud, analytics kind of engineering technologies to achieve their business goals. One of the leading companies in the food segment having a presence across the globe and manufacturing setup in India approached us for the Remote SCADA solution.

Challenge:

Temperature and other critical parameters need to be managed as per the desired range as it will impact the working of all inventory products. It would be a huge loss for the company if the temperature is out of the range even for a few minutes.

Solution:

Implemented redundant PLC System along with the mobility solution for the fast response time. Maintenance & production related critical parameters like outlet temp, Inlet temp, pressure, uptime, preventive maintenance schedule, and Overall Equipment Efficiency (OEE) are available with a single click and all critical alarms have been automatically sent through the mail & through messages on mobile phones. This solution helps customers to make uptime high.